Zojirushi has been in the vacuum insulation business for over 100 years! The company opened its doors in Osaka as the Ichikawa Brothers Trading Company in 1918 manufacturing vacuum liners, and began manufacturing vacuum bottles in 1948. We’ve been designing vacuum insulated products since then!

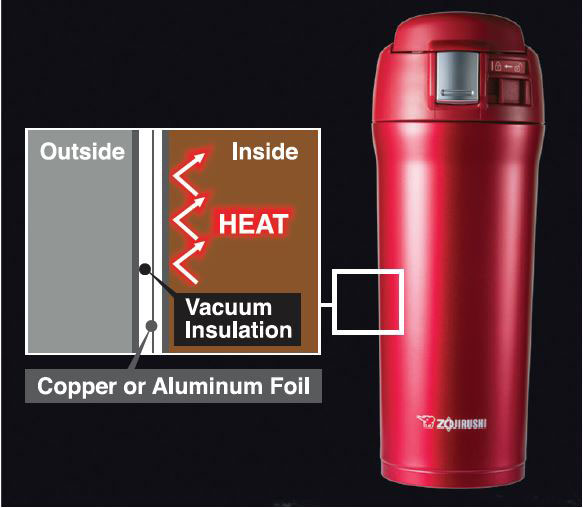

Vacuum insulation is a specific type of insulation that uses a man-made vacuum between two panels of materials, such as glass or stainless steel, so that the temperature of the fluids or gases on either side of the panels are isolated and don’t affect each other. The concept of a vacuum insulated flask was originally developed in the West in 1892 by James Dewar, a scientist who was interested in cryogenics and in developing supercooled substances like liquid hydrogen. Dewar needed a way to keep the liquid hydrogen cool, so that it wouldn’t evaporate, and came up with a vacuum insulated flask made of two walls of glass. Vacuum insulated glass containers were at the heart of Zojirushi’s technology, until 1981, when we created our TUFFBOY line and patented the process to make vacuum insulated stainless steel containers.

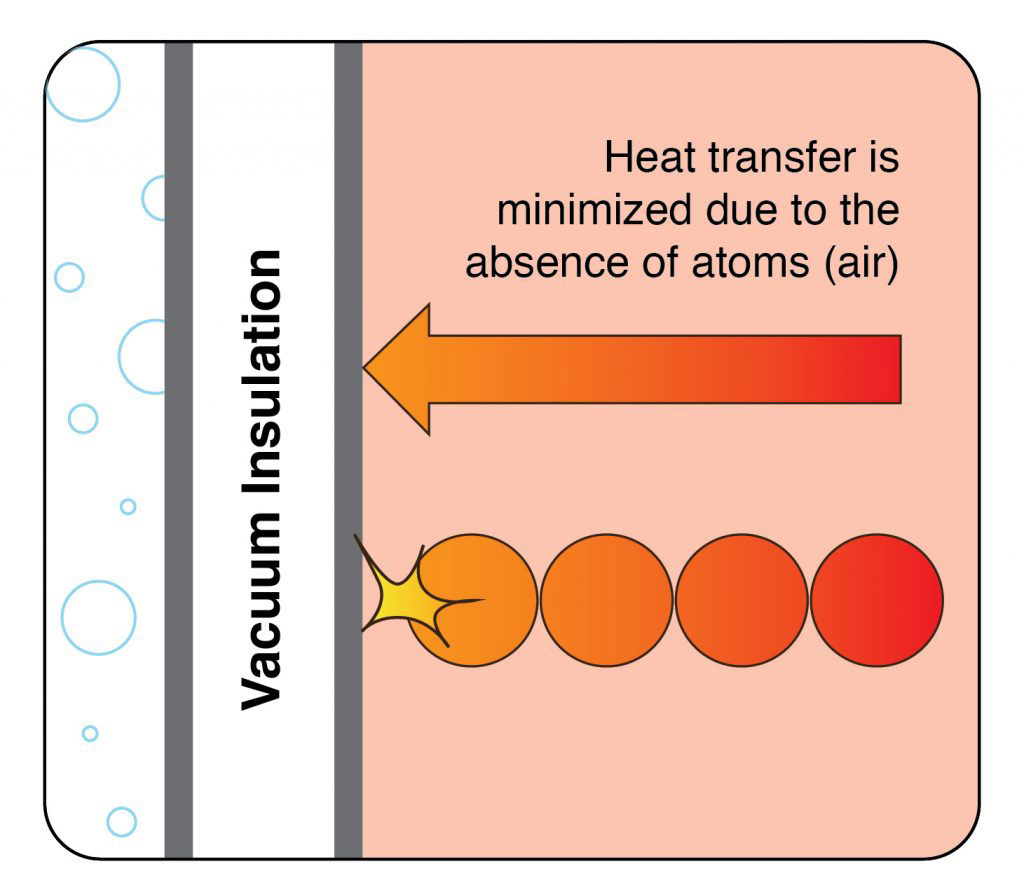

Vacuum insulation has many benefits, which we’ve incorporated into our bottles, mugs, food jars, and lunch jars since the first vacuum bottle. The first benefit is the superior insulation. Vacuum insulation prevents heat loss through conduction. Since the air – which is a conductor – is removed between the inner and outer layers of stainless steel, heat isn’t transferred. In fact, a gap as small as 1 mm for the air can insulate the food or drink inside your container!

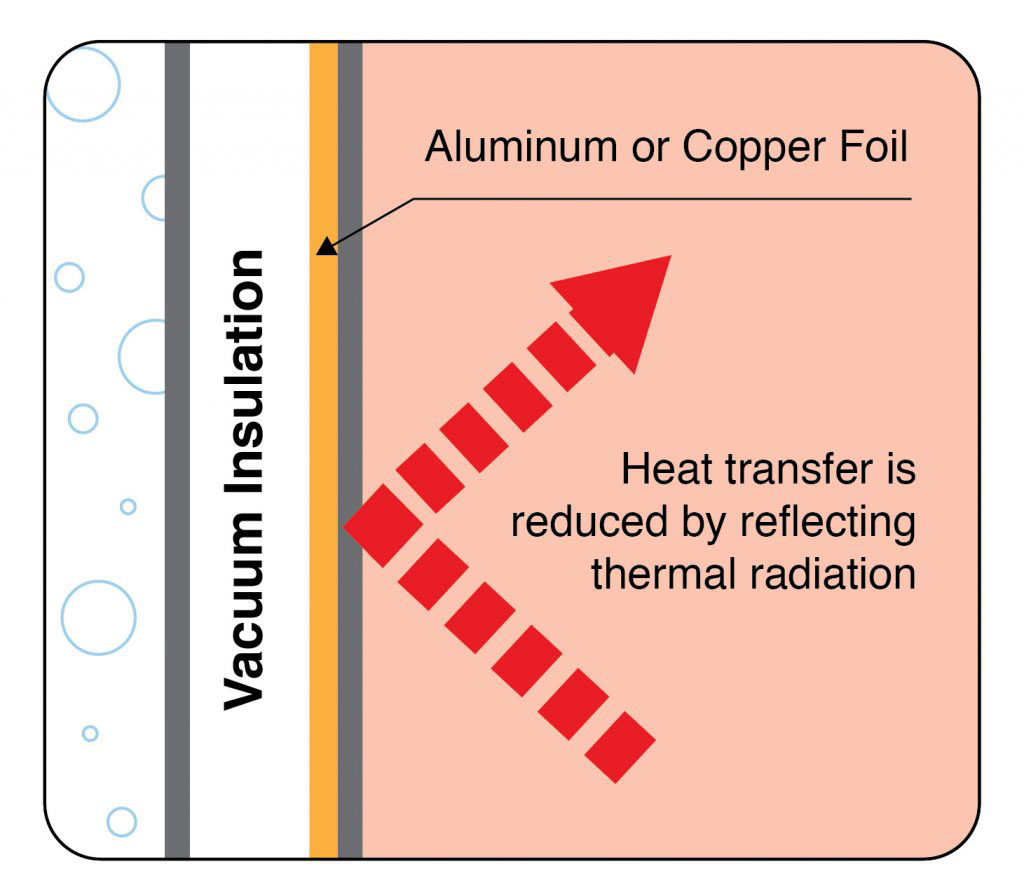

If you remember from your school days, there are 2 other ways heat can transfer: radiation and convection. In a Zojirushi bottle, heat transfer is also prevented by insulating against radiant heat transfer. A thin sheet of aluminum or copper is wrapped around the outer surface of the inner layer to help reflect radiant heat.

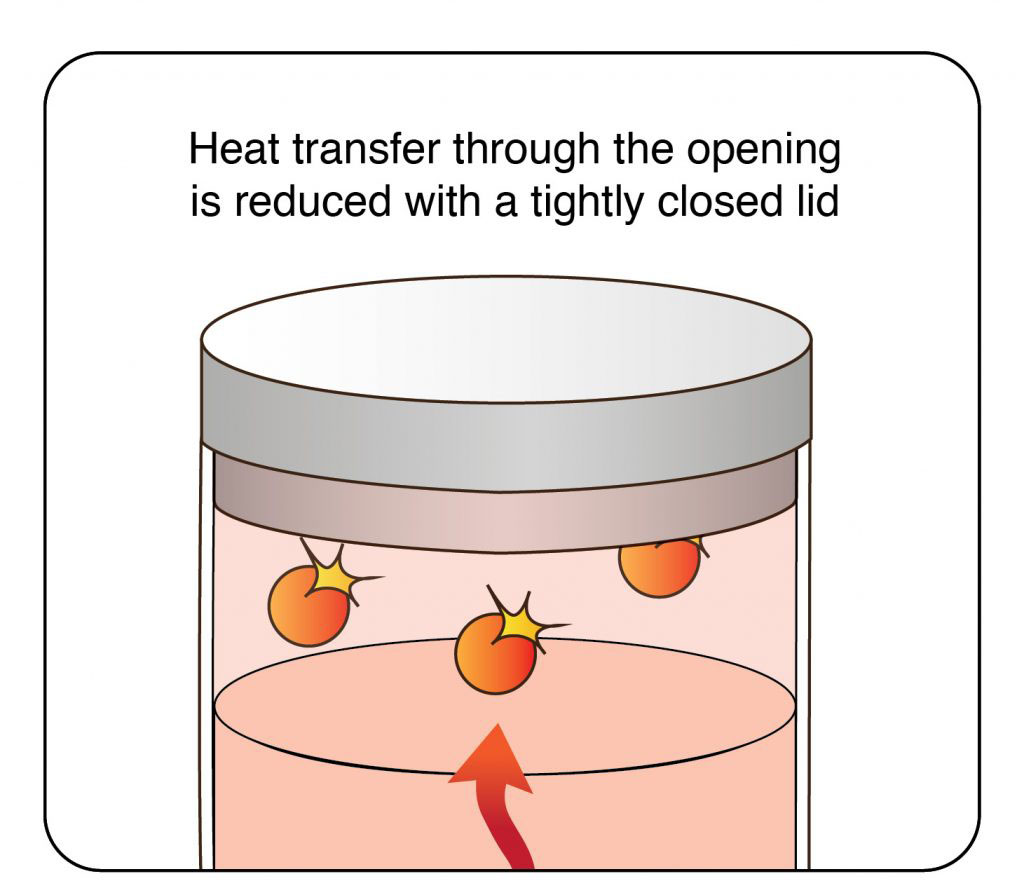

And finally, heat transfer through convection is blocked by tightly sealing the lids on each of the products. For bottles, mugs, and food jars, the lid itself is equipped with a gasket to seal it onto the container, whereas lunch jars use a foam-insulated inner lid. Each of these three ways keeps food and beverages hot or cold for hours.

Along with managing heat transfer, using vacuum insulation makes all of our products lighter. Many thermal vessels use polystyrene foam or the addition of other materials to insulate, adding weight and bulk. Our vacuum insulation makes our products lighter and more compact.

Our superior vacuum insulation makes it easy to choose your favorite bottle, mug, food jar, or lunch jar. Pick between a non-stick coated or SlickSteel® interior. Choose the right size and capacity. And select your favorite color. Check out our full line up in the Products section, and be sure to comment with any questions you might have.

Leave a Reply